Export of products

to GUS- countries, Egypt, Sudan, Venezuela

Rotary ovens series PR

- Universal high-performance ovens high efficiency

- The opportunity to work on various types of fuel (gas, electricity, diesel fuel)

- Possibility of installation on small floor spaces

For baking a wide the range of bakery and confectionery products in terms of active operation enterprises the baking industry

Technical characteristics:

| Model | PR-100 | PR-120 | PR-150 | PR-200 |

| Productivity, kg/h, not less | ||||

| the loaf 0.4 kg | 125 | 160 | 250 | 300 |

| the bread 0.8 kg | 100 | 123 | 227 | 284 |

| Overall dimensions of the pallets, mm | ||||

| length × width | 790×590 | 790×590 | 1062×750 | 790×590 |

| Maximum load on the cart. | ||||

| the loaf 0.4 kg | 104 (13) | 136 (17) | 255 (17) | 256 (16) |

| the bread 0.8 kg | 96 (8) | 120 (10) | 240 (10) | 240 (10) |

| The consumption of fuel used* | ||||

| gas, m3/h | 8, 5 | 9 | 10,0 | 10,0 |

| liquid, kg/h | 6,8 | 7,2 | 8,0 | 8,0 |

| Water consumption, l/h | 6 | 8 | 23 | 23 |

| The working gas pressure, kPa | 2,0-4,5 | 2,0-4,5 | 2,0-4,5 | 2,0-4,5 |

| Installed power, kW | ||||

| – electrically heated | 54 | 54 | 85 | 85 |

| – on gas fuel | 3 | 1,8 | 3 | 3 |

| – diesel | 1,8 | 3 | 3 | 3 |

| Overall dimensions, mm | ||||

| length ×width ×height (gas outlet pipe) |

1600×1600×2153 (2306) | 1615×1620×2466 (2597) | 1800×1870×2480

(2749) |

1900×2020×2480

(2749) |

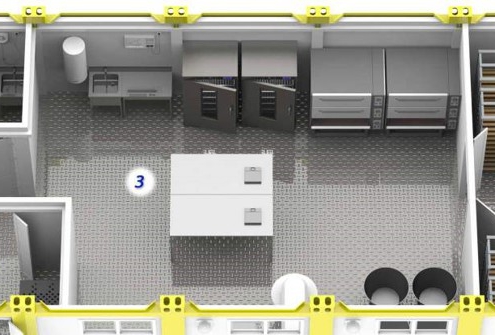

Convection oven series PK

- Ideal for small businesses, pastry shops, restaurants, shops

- The ability to work on different types of fuel (gas, electricity)

- The products are baked on aluminum pallets

- Small size (footprint less than 1m2).

- Uniformity of baking is height adjustable blinds.

- Improved steam.

For baking a wide assortment of small bakery and confectionery, as well as heating and cooking

Technical characteristics:

| Модель | ПК-5Э | ПК-9Э | ПК-9Г |

| Productivity, kg/h, not less | 48 | 65 | 65 |

| The number of pallets, PCs. | 5 | 9 | 9 |

| Overall dimensions of the pallets, mm | |||

| length × width | 600×400 | 600×400 | 600×400 |

| area of grate, m2 | 1,2 | 2,16 | 2,16 |

| Installed power, kW | 7,5 | 14,5 | 1,2 |

| Rated voltage | 380/220±10%, 50 Гц | ||

| Gas consumption, m3/h | – | – | 2 |

| Overall dimensions, mm, not more | |||

| length ×width ×height | 1040×850×866 | 1040×850×1280 | 1280×850×1300 |

| Weight, kg, not more | 210 | 280 | 320 |

- Universal high-performance ovens high efficiency

- The ability to work on different types of fuel (gas, electricity)

- Download of the dough pieces on the trucks (which increases performance)

- small size (footprint less than 1.5 m2)

- evenness of baking (without relocating the pallets)

- simultaneous download of products a wide range

For baking bread, bakery products, flour confectionery products

Technical characteristics:

| Model | PK-16Э | PK-16Г |

| Productivity, kg/h, not less | ||

| a loaf of sliced 0.4 kg | 86 | 86 |

| form No. 10 | 49 | 49 |

| The number of pallets, PCs. | 16 | 16 |

| Overall dimensions of the pallets, mm | ||

| length × width | 600×400 | 600×400 |

| area of grate, m2 | 3,84 | 3,84 |

| Installed power, kW | 30,3 | 2,2 |

| Rated voltage | 380/220±10%, 50 Гц | 380/220±10%, 50 Гц |

| Gas consumption, m3/h | – | 3,2 |

| Overall dimensions, mm, not more | ||

| length ×width ×height | 1575×885×1930 | 1575×885×1950 |

| Weight, kg, not more | 420 | 480 |

Cabinets preliminary proofing series SHPR

Pre-proofing takes place during the movement of dough pieces on the baskets at ambient temperature without forced heat

The mechanism of loading and unloading of the test has three versions (left, right and rear)

can be easily integrated into any production line

the ability to control time proofing

convenience visual monitoring of the proofing process

For mechanized process preliminary proofing dough pieces after rounding

Technical characteristics:

| Model | SHPR-1 | SHPR-2 | SHPR-3 | |

| Productivity, PCs/h | 2000 | 1500-2160 | 1200-1560 | |

| The weight of the dough pieces, g | от 300 до 600 | от 150 до 800 | от 150 до 800 | |

| The number of cradles | 34 | 26/32/36/40 | 26/32/36/40 | |

| The number of baskets in the same cradle | 8 | 6/8 | 6/8 | |

| Installed power, kW | 0,65 | 1,4 | 1,0 | |

| Proofing time, min. | 8 | 4-6 | 5-8 | |

| Nominal voltage, | 380/220±10%, 50 Гц | 380/220±10%, 50 Гц | 380/220±10%, 50 Гц | |

| Type of current | Three phase, AC | Three phase, AC | Three phase, AC | |

| Overall dimensions, mm, not more | ||||

| length ×width ×height | 1800×1190×2500 | 2400×2300×2600 | 1798×2300×2600 | |

| Weight, kg, not more | 440 | 800 | 700 | |

The synchronicity of the movement of the test workpiece and the position of the cradle is monitored by the optical sensors

Available in various versions:

- 2 or 4 truck

- Through or dead-end

ADVANTAGES:

- collapsible design for easy portability

- saving heat and electricity through the use of modern materials

Maintaining the specified parameters and visual inspection temperature and humidity inside the Cabinet is carried out using climatic installation TVG

Technical characteristics:

| Model | ON 2 truck entrance | On 2 truck a dead end | 4 a trolley pass-through | On 4 truck a dead end | On 2 truck a dead end |

| Overall dimensions, mm, not more | |||||

| length ×width ×height | 2200×1400×2000 | 2160×1400×2000 | 2300×1400×2000 | 2350×2370×2000 | 1000×1700×1900 |

| Weight, kg | 350 | 350 | 420 | 420 | 300 |

| The maximum sizes of trucks, mm | |||||

| length ×width ×height | 1120×850×1880 | 1120×850×1880 | 1120×850×1880 | 1120×850×1880 | 600×450×1592 |

For use in the composition of technological lines for the production of a wide range of bakery products

The volume of different bowls (depending on model)

ADVANTAGES:

- equipped with hopper of stainless steel

- simultaneous rotation of the bowl and kneading of the body

Dough dividing machine series TD

For use in the composition of technological lines for the production of a wide range of bakery products

Ensure accurate division of the dough pieces, the recommended moisture content of the test from 38% to 43%

Ensure accurate division of the dough pieces, the recommended moisture content of the test from 38% to 43%

ADVANTAGES:

- The piston-vacuum principle of operation (does not disturb the test structure)

- Adjustable weight and number of blanks

- You can choose the required machine performance (speed division)

For mechanized divide the dough on the test workpiece the required weight

Technical characteristics:

| Model | TD-110/1 | TD-125/1 | TD- 70/2 |

| Technical performance PCs/hour, not less |

1000, 1300,

1800 |

1000, 1300, 1800 | 2000, 2600,

3600 |

| Weight obtained dough pieces, g | от 150 до 500 | от 200 до 700 | От 50 до 120 |

| Installed power, kW | 1,5 | 1,5 | 1,5 |

| Nominal voltage, | 380/220 | 380/220 | 380/220 |

| Hopper volume load test, kg | 50 | 50 | 50 |

| Nominal current frequency, Hz | 50 | 50 | 50 |

| Overall dimensions, mm, not more | |||

| length ×width ×height | 1430×530×1500 | 1430×530×1500 | 1430×530×1500 |

| Weight, kg, not more | 560 | ||

The machine can be equipped with (optional) a device for the separation of the dough pieces into two equal parts

A divider with a capacity of 1,500 and 3,000 pieces/hour

Designed for accurate dividing of the dough pieces from wheat and rye dough weighing from 50 to 1000 grams

Differ gentle effect on the dough with the use of the hydraulic system of compensation for the efforts of the discharge

Performance max:

- Single-piston setup – 1500 шт/час

- Two-piston setup – 3000 шт/час

- Single-piston setup – 150 – 2000 г

- Two-piston setup – 50 – 1000 г

- Installed power : 1,23 kW

Dough rounder series BTO and HTO:

Technical characteristics:

| Model | BTO-100 | HTO-2500 | HTO-2500У |

| Technical capacity, PCs/hour | 2000 | 3600 | 2000 |

| Weight of processed dough pieces, g | от 100 до 600 | от 50 до 1000 | от 50 до 1000 |

| Installed power, kW | 1,1 | 3,0 | 3,0 |

| Power consumption, In | 380/220 ±10%, 50 –0,5 Гц | 380/220 ±10%, 50 –0,5 Гц | 380/220 ±10%, 50 –0,5 Гц |

| Type of current | Three phase, AC | Three phase, AC | Three phase, AC |

| Overall dimensions, mm, not more | |||

| length ×width ×height | 1100×1000×1355 | 1323×1165×1520 | 1323×1165×1520 |

| Weight, kg, not more | 200 | 500 | 500 |

The possibility of installation in any production line

The possibility of installation in any production line

ADVANTAGES:

- The exception of sticking of workpieces expense of blowing off work surfaces

- Automatic adding of flour

- Coating okreslonego cone and gutters polymer coating

Dough moulding machine series TZM:

It is used to produce a wide variety of bakery products in the composition of technological lines

In the process, through the distribution of gases in the dough piece is a more uniform porosity of the crumb

ADVANTAGES:

- The presence of 3 pairs of rolling rolls

- The rolls in the rolling mechanism is provided with a knife for self cleaning

- Feeding and conveyor belt have a tensioner

For mechanized give oblong shape the dough pieces

Customer Reviews :

“Working on this equipment, we were able to increase the amount of baking and selling 30%. Observations on the operation of the equipment. ( “Russian stove”, Tashkent, Uzbekistan)

“More than 10 years bake their products in furnace engineering plant. The oven is simple to operate, economical. Baking is of excellent quality”. (Aigul” Tashkent region, Uzbekistan)

“More than 10 years bake their products in furnace engineering plant. The oven is simple to operate, economical. Baking is of excellent quality”. (Aigul” Tashkent region, Uzbekistan)

“On the equipment of machine-building plant Shebekinsky have been working for many years. In the process of operation it showed itself as a reliable, economical, performing their functions and tasks at 100%. Ready to continue to cooperate with Shebekinskiy plant”. (JSC “Khlebozavod №2”, Voronezh, Andronnikov V. N. CEO)

“For a long time cooperating in Shebekinskiy of Mashzavod. The supply of equipment were in various enterprises of the Siberian region”. (TD “Borodino” Omsk)

Reference Sheet:

Equipment for mini-bakeries production SHMZ successfully used for baking enterprises not only in Russia but also the CIS countries:

ZAO Kurskkhleb (Kursk, Russia)

ZAO Kurskkhleb (Kursk, Russia)- JSC “Bread of Meshchera (Vladimir oblast)

- OAO “Khlebozavod № 2” of OJSC “Bakery plant № 7” (Voronezh)

- The Corporation GRINN (Orel)

- The company “Bread Peace” (Barnaul)

- JSC Chelny-Khleb” (Naberezhnye Chelny)

- ZAO Khlebozavod Belev (Tula region)

- Potrebobschestvo Balezino (Udmurtia), etc.

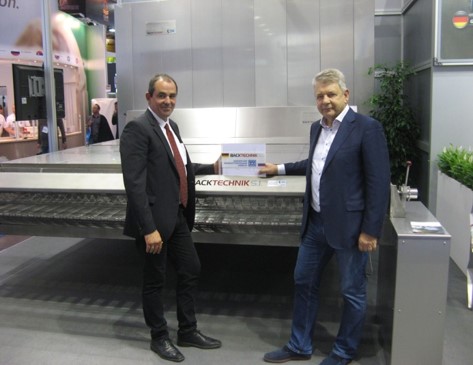

Exhibition :

Annually Shebekinsky machine-building plant takes part in international and regional exhibitions:

- Modern Bakery (Moscow)

- Agroprodmash (Moscow)

- exhibitions in Kazakhstan, Azerbaijan, Uzbekistan, Belarus etc.

In 2015, the plant together with the German company Backtechnik partners took part in the largest international exhibition IBA

Trading , Contracting , Consulting , Visibilty & Market Study

Contact Us

![]()

Syria – Damascus – Pakistan Street Al-Urfa building, 1st floor No. 4

![]()

+963 11 44 37 337

![]()

+963 932 737 070

![]()

info@rsmco.net

Opening Hours

Sat-Thurs: 9:00 Am- 5:00 Pm